When it comes to enhancing your Jeep for off-road adventures, installing lights is an essential upgrade that can significantly improve visibility during nighttime excursions. Proper wiring techniques are crucial not only for functionality but also for ensuring safety on the trails. In this article, we will explore some important tips to help you successfully wire your off-road lights.

Understanding the basics of electrical systems and how to effectively route wires can prevent common issues such as short circuits, flickering lights, and even potential damage to your vehicle’s electrical system. With the right approach, you can achieve a clean and reliable setup that enhances both the look and performance of your Jeep.

From selecting the right gauge of wire to understanding the importance of grounding, mastering these techniques will take your off-roading experience to the next level. Whether you’re a seasoned off-roader or a newcomer, the following tips will guide you through the wiring process to ensure your lights shine bright when you need them the most.

Choosing the Right Wire Gauge for Jeep Light Installations

When installing lights on your Jeep, selecting the appropriate wire gauge is crucial for optimal performance and safety. The wire gauge determines the amount of current that can safely travel through the wire without overheating or causing a short circuit. It’s essential to match the wire size with the power requirements of the lights you intend to install.

Typically, the American Wire Gauge (AWG) system is used for automotive wiring. For off-road lights, a wire gauge between 12 and 16 AWG is generally recommended. If you’re installing high-intensity lights, such as LED bars or high-wattage halogens, consider using a 12 AWG wire. This gauge can handle higher current loads effectively and reduces the chance of voltage drop.

When choosing a wire gauge, it’s essential to refer to the manufacturer’s specifications for the lights. Check the amperage draw of each light and calculate the total current required for your setup. If the total exceeds 15 amps, a thicker wire, like 10 AWG, may be necessary to ensure safe operation.

Here are some tips to keep in mind when selecting wire for your Jeep light installations:

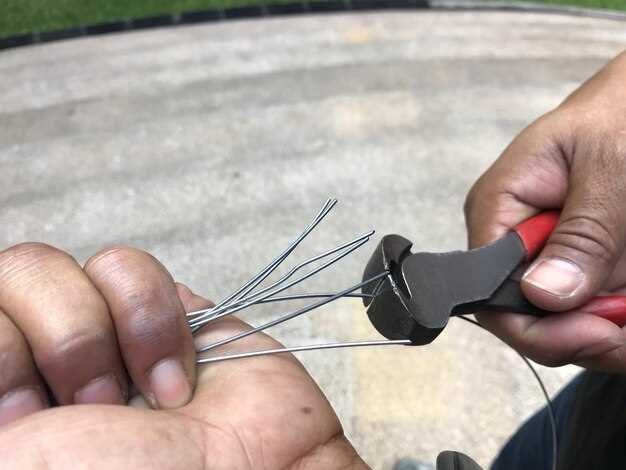

- Always use stranded wire for better flexibility and durability in off-road conditions.

- Using a fuse matched to your wire gauge will provide an added layer of protection for your electrical systems.

- Consider the length of the wire run; longer distances may require a lower gauge to prevent voltage drops.

By taking the time to choose the right wire gauge, your Jeep’s lighting system will not only perform better but will also enhance safety during your off-road adventures.

Understanding Relay Systems for Off-Road Lighting

Relay systems play a crucial role in the effective wiring of off-road lights. They act as electronic switches that help manage high-current demands without overloading the vehicle’s stock wiring. This is particularly important for off-road applications where lights often draw significant power.

Using a relay system ensures that the power needed for the lights is supplied directly from the battery instead of routing through the vehicle’s existing circuits. This approach minimizes voltage drop, thus maximizing the brightness and efficiency of the lights. When installing off-road lighting, it’s crucial to use a relay to handle the high amperage associated with most aftermarket lights.

Here are some tips for correctly implementing a relay system for your off-road lighting: First, choose a relay rated for at least the combined amperage of all lights you plan to install. A 30-amp relay is commonly sufficient for multiple lights. Second, ensure proper wiring gauge; using a thicker wire reduces resistance and prevents overheating. Third, include a fuse in the circuit to protect against potential shorts.

To connect the relay, you will wire the switch to the trigger terminal on the relay, and then connect the power input directly from the battery to the relay’s common terminal. The output terminal will wire to the lights themselves. This method keeps the switch safe from heavy currents and enhances longevity.

By understanding and employing relay systems in your off-road lighting setup, you enhance both the safety and functionality of your vehicle’s lighting capabilities. Implementing these techniques will result in more reliable performance, ensuring that your lights shine bright even in the toughest conditions.

Common Wiring Mistakes and How to Avoid Them

When installing off-road lights on your jeep, proper wiring is crucial for efficiency and safety. Common mistakes include using inadequate wire gauge, which can lead to overheating and potential failure of the lights. To avoid this, always calculate the appropriate wire gauge based on the current requirements of your lights.

Another frequent error is improper grounding. Poor grounding can result in flickering lights or even damage to the electrical system. Ensure all connections are clean and secure, and utilize a dedicated grounding point on the jeep’s chassis to establish a solid electrical connection.

Neglecting to fuse the wiring is a significant oversight that can cause damage to both the jeep and the lights. Always include a fuse appropriate for the circuit to protect against short circuits and electrical surges.

Additionally, failing to use weatherproof connectors can lead to corrosion and malfunction, especially in off-road environments where exposure to elements is common. Opt for premium, weather-resistant connectors to maintain reliability over time.

Lastly, routing wires improperly can result in wear and tear, as excessive movement might cause wires to fray and short. Plan the wire route carefully, securing it away from moving parts and using protective conduit where necessary to safeguard the wiring.